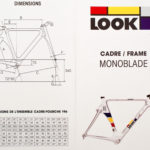

The Look KG 196 is the bicycle equivalent of techno music: no matter how many decades pass, it still looks like a radical vision of the future. First introduced in 1993, the Look KG 196 introduced several groundbreaking new developments in the design and manufacture of carbon bicycles. Most modern carbon bikes can trace their roots directly back to the KG 196, with its monocoque frame design and radical Monoblade fork. I spent almost a decade searching for one in my size, and finally found one in early 2020. It took another two years to build it up with a carefully chosen parts kit designed to balance the kind of riding I like to do with components that compliment the aesthetics of the bike. Read on for more photos and history of the Look KG 196!

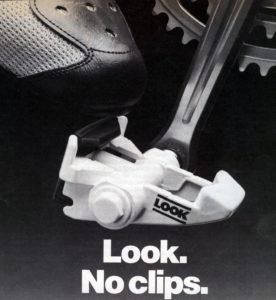

Founded in 1951 by cyclist and skier Jean Beyl, Look developed an new safety binding system for skis in 1963 that allowed the user to remove their boot from the binding by rotating their foot. The new binding would also release under a certain amount of torque, greatly reducing the chances of a broken ankle during a fall. This was applied to bicycle pedals in 1984, creating the first “clipless” pedal. Used by professional rider Bernard Hinault in his 1985 Tour de France win, this new invention took the cycling world by storm.

Founded in 1951 by cyclist and skier Jean Beyl, Look developed an new safety binding system for skis in 1963 that allowed the user to remove their boot from the binding by rotating their foot. The new binding would also release under a certain amount of torque, greatly reducing the chances of a broken ankle during a fall. This was applied to bicycle pedals in 1984, creating the first “clipless” pedal. Used by professional rider Bernard Hinault in his 1985 Tour de France win, this new invention took the cycling world by storm.

Not content to sit on their laurels, Look debuted their first carbon frame in 1986, the Look KG 86. TVT but went under the name of Look KG86. Greg Lemond won the Tour De France in 1986 using a Look KG 86 fitted with Campagnolo C-Record components.

Not content to sit on their laurels, Look debuted their first carbon frame in 1986, the Look KG 86. TVT but went under the name of Look KG86. Greg Lemond won the Tour De France in 1986 using a Look KG 86 fitted with Campagnolo C-Record components.

Manufactured for Look by TVT, it exemplified the standard frame construction technique for carbon fiber bicycles in the 1980s. Much like aluminum bicycles of that era, frames were constructed from carbon fiber tubes joined by cast aluminum “lugs” and held in place by a combination of chemical (glue) and mechanical (pins) means.

This technique is often referred to as “screwed and glued” and dates back to the 1930s when French brands Caminade and Mecadural debuted the first aluminum frames. The KG 86 was followed by the KG 96, which debuted in 1991. Kevlar was woven into the tubes for added stiffness and strength.

The KG 96 was ridden by the Toshiba, Gan, and Credit Agricole teams in the early 1990s. Lugged carbon bikes are still produced today, especially in the world of custom-made bicycles. However, the manufacturing process is complex and limits the frame design to a traditional tube-based approach. The KG 196 would revolutionize carbon fiber bicycle design through the introduction of the monocoque frame.

Monocoque carbon frames do not use tubes; instead the carbon fiber is molded into single integral construct. This helps to distribute dynamic stress over a wider portion of the frame, avoiding the weak spots that tend form at the joints of lugged carbon frames. The one-piece construction of a monocoque frame also sets designers free from the limitations of a tube-based frame, allowing them to design the most aerodynamic shapes possible.

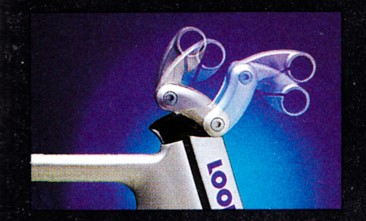

The frame features a massive down tube and bottom bracket area optimized for air flow, and the seat stays create small “shoulders” to better channel the air around the rear brake. The most distinctive feature was the namesake Monoblade fork. It was the first integrated fork ever used on a production bicycle, and connects to the frame by a single pivot with an elastomer insert to reduce vibrations caused by rough roads. All of these features resulted in an incredibly stiff frame with excellent power transfer, great aerodynamics, and stunning looks.

The Look KG 196 was ridden by professional teams ONCE and Festina in the early 1990s, with riders Alex Zülle (pictured above racing a time trial at the 1993 Vuelta a España), Laurent Jalabert and Australian national champion Neil Stephens. The monocoque design inspired further innovations from Look’s competitors, leading to out-of-this-world designs like the Lotus 110 and Corima Cougar. Concerned that the new technology gave riders an unfair advantage, in 1996 the UCI (the world governing body of cycling) significantly limited the types of designs permitted. Despite this, many of the innovations pioneered by the KG 196 can be found in today’s bicycles. Monocoque designs are now the most common type of carbon fiber frame, and Monoblade fork designs have reappeared in everything from race bikes to New York City’s bikeshare “Citibikes“.

KG 196 bicycles are notoriously difficult to find, as they were both a rare and high-end bike in their day, and are still ridden competitively today by triathletes and time trialists. It’s even harder to find one in a smaller size, and it was years before I found this bike on eBay France (ebay.fr), located in a small town in France. Originally, the bike arrived with a modern SRAM Red group set and carbon tubular wheels. I removed these parts and replaced them with an all-Campagnolo build that is evocative of the 1990s while providing modern shifting and a wide-range cassette.

The above photo is the final iteration of the build: Campagnolo Centaur 10-speed drive-train with compact crank and long-cage derailleur, Veloce shifters and brakes, and a Campagnolo Zonda wheelset. I switched out the Ergostem for a period-correct 26.0mm clamp silver version (it had originally arrived with a later 31.8mm oversized clamp) and installed NITTO “Noodle” road handlebars. The Campagnolo Zonda wheels, from the early 1990s and normally limited to 8 speeds, were custom modified to accept 9, 10, or 11-speed cassettes. As shown in the first photo, I was previously riding a Campagnolo Shamal HPW-12 wheelset with the same modification, but with only 12 spokes per wheel, they’re not suited to the rough streets of my home city.

I’ve put a lot of miles on my KG 196 and love the ride. It’s stiff without rattling your teeth or killing your joints, and launches into high speed the second you start mashing the pedals. I’ve spent all day on it several times, and never felt tired out by the ride. It is long and low; I might actually be better suited to the 52cm size when you look at how I have positioned the Ergostem. However, I’m happy with my machine and plan to continue riding it for years to come. Check out the gallery of hi-res images below, including a frame geometry sheet and Italian advertisement.