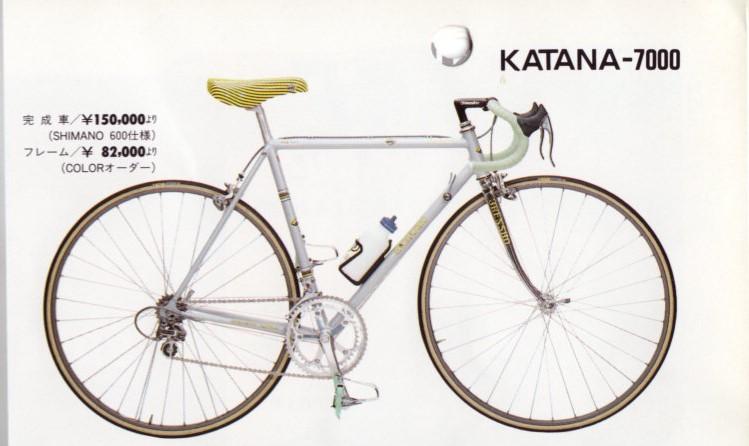

Translation: “With a basic weight of 8.9kg, the 7000 series aluminum frame produces the lightness and stiffness required for racing.”

In the early 1990s, TIG-welding was rapidly eclipsing the “screwed and glued” method of aluminum bicycle frame construction. At the same time, aluminum frames were enjoying peak popularity among professional racers, being ridden to victories in the Tour de France and other major events. This was the era of stiff, lightweight aluminum race bikes with extra-skinny tires, and 3Rensho was not going to be left behind. Enter the Yamakuni 7000 bicycles, which would replace the SR Litage in the final years of 3Rensho. Before we get there, let’s dig into a brief history of welded aluminum frames after the jump.

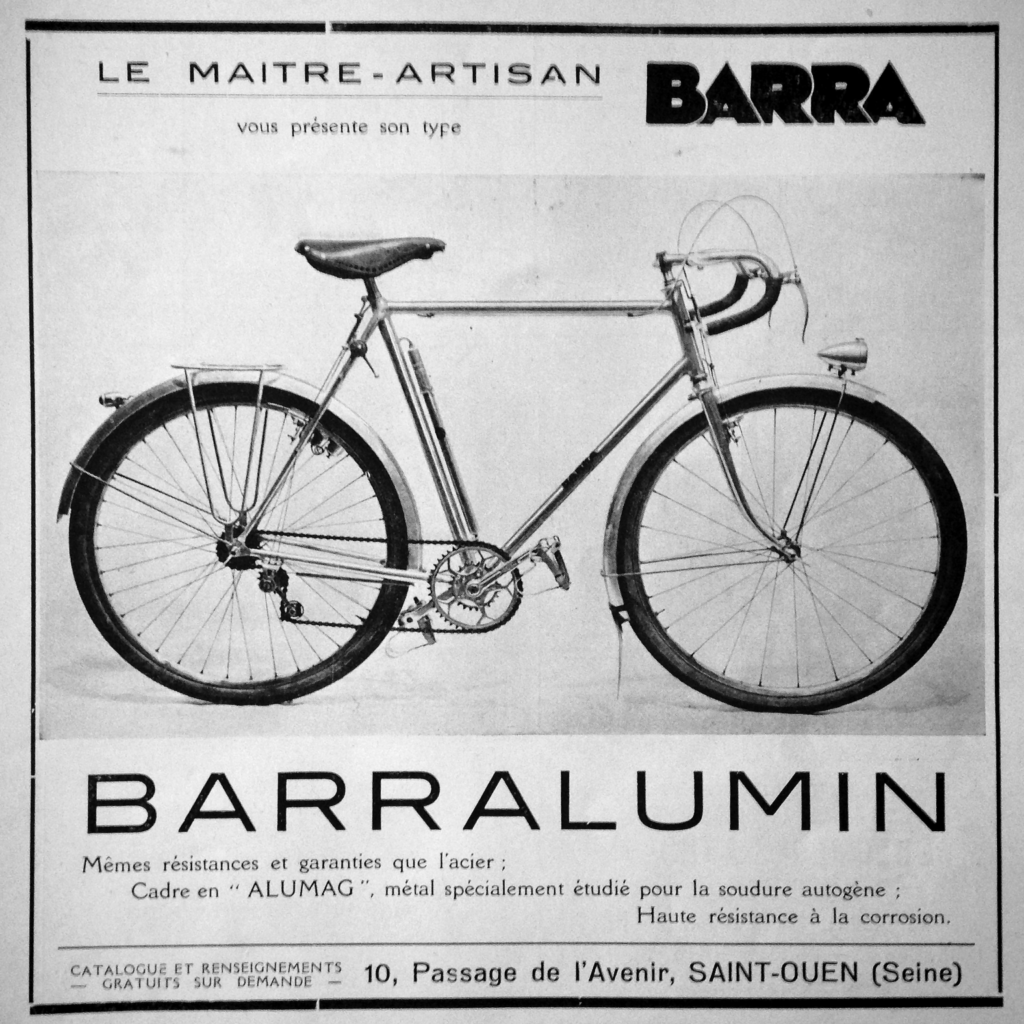

Welding aluminum frames was not a new concept; it dates back to at least the 1930s-1940s when Duralumin (an early hardened aluminum alloy) began to be used first in bicycle components, and then frames. The most well-known maker of welded aluminum frames of the period was Frenchman Nicolas Barra:

Nicolas Barra was one of the true geniuses in the history of lightweight bicycles. His first welded aluminium bike took part in the 1936 Grand Prix du duralumin. He then produced a number of these fantastic sculptural frames under the name Barralumin. They were a total revolution compared to the bolted or glued alloy frames used at the time. A few frames were used in the Tour de France, most famously by Vietto. The welding required great skill, and a technique that Barra invented himself.

Due to the immense level of skill needed to weld aluminum, these bikes were never produced in a large quantity, and surviving Barra bikes are valuable collector’s items.

In the 1970s, another Frenchman by the name of André Sablière revived the craft. The son of famous constructeur Charles Sablière, his welded aluminum frames are graceful works of art. He continued hand-making these frames into the 1990s, and while he is now retired, he is still active on Facebook.

1990s Sabliere welded aluminum bicycle with Dura Ace 7400.

Of course, it’s impossible to overlook the American contributions to this story. An early innovator was Harlan Meyer, who used large-diameter aluminum tubing in a frame with riveted joints to produce the Cosmopolitan bicycle in 1971, under his brand Hi-E.

Combining large-diameter aluminum tubes with welded joints seems to date back to the early 70s. Bill Shook, who would go on to found the American Classic brand, built and raced on his own welded frame in 1974. Around the same time, welded aluminum prototype frames were being developed by students in a M.I.T. research group led by professor Shawn Buckley, which was investigating alternatives to steel as bicycle frame material. Among the students in this group was Gary Klein. While not the first student to produce a frame, his came in 1975, and by 1981 had his first production run available. In 1983, Cannondale debuted their first bicycle, the ST500, a TIG-welded frame with oversized aluminum tubes. Gary Klein sued Cannondale in the 1980s claiming patent infringement, but lost the case when Cannondale was able to provide multiple examples of welded frames pre-dating Klein’s. For more info, see this Bikeforums thread and this article on Sheldon Brown’s website.

Figuring out who made 3Rensho’s welded aluminum frames was tricky. I imported the above lo-pro pursuit frame from Japan in 2020, but unlike the SR Litage, there was no clear branding on the frame other than 3Rensho. It wasn’t until I noticed the tubing sticker that I had my first clue:

It reads: Nippon Light Metals Yamakuni 7000 Series.

It reads: Nippon Light Metals Yamakuni 7000 Series.

I discovered that they weren’t just a tubing supplier, they were actually one of the first Japanese companies to mass-produce welded aluminum frames. They made the 1986 Centurion Facet, and possibly the Miyata Omnium, Diamondback Arrival, and the Kuwahara Maragay MTB. Yamakuni and also made bikes under their own brand, including the “Yamakuni Wolf” and “Country Bird” MTBs, and an unnamed road bike identical to the Facet.

Yamakuni made two models for 3Rensho: the Katana 7000 road bike, and the XR-7000 lo-pro pursuit bike. Both are featured in a 3Rensho catalog from the early 1990s, and have chrome steel forks. The fork on my XR-7000 uses the familiar 3Rensho aero fork crown, so 3Rensho may have manufactured the forks in-house. One other detail not seen on any other frames made by Yamakuni is the “fast-back” style of seat post binder, where the bolt runs through the tops of seat stays, an innovation credited originally to Cinelli.

While I again don’t have any insights from the folks running 3Rensho at that time, I suspect they were aware of the fact that the SR Litage was available under a variety of brands and wanted their next foray into aluminum to be a uniquely 3Rensho product, even if the frames weren’t made in-house. Below are some photos of the Katana 7000 road bike from Facebook, built up with the same Dura Ace 7400 group as pictured in the 3Rensho catalog:

Here is one complete example of XR-7000 pursuit bicycle built up with Shimano Sante components. It uses a 700c rear wheel and a 24″ front wheel for a very aggressive geometry:

For months, I struggled to find a matching 700c/24″ wheelset or a set of matching rims from which to build up my frame set. Then I realized I could find one inexpensively by acquiring a Georgina Terry womens’ bike, which used this combo as a standard spec. I found a barely-ridden Georgina Terry Despatch and stripped it down for the wheelsets and a stash of very clean Suntour Cyclone 7000 components. I’m now tracking down the last pieces of the cockpit that I need to finish the build. Like my 3Rensho Litage, I’m excited to see how these bikes ride and compare to my steel 3Renshos.

Below is a gallery of my 3Rensho XR-7000 frameset, as well as a high-res scan of the 3Rensho catalog it and the Katana 7000 appear in. In the final installment of this series, I will dig into 3Rensho’s forays into carbon fiber!

Pingback: 3Rensho XR-7000 Lo-Pro Pursuit Funny Bike | djcatnap.com